Process development

LightPulse

LASER PRECISION ─

A focus on precision with ultrashort pulse lasers

Processes from the expert

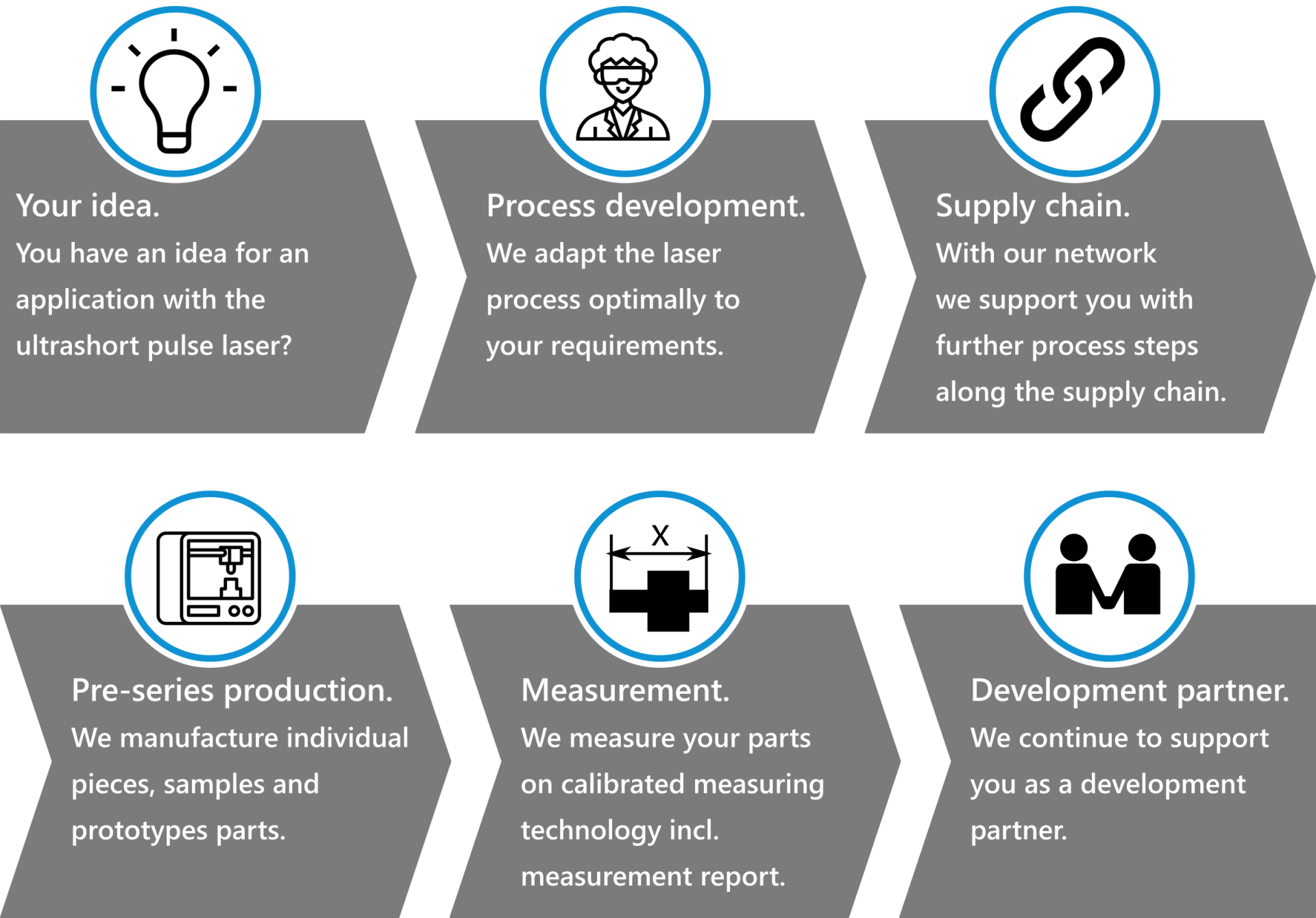

The ultrashort pulse laser offers an enormous flexibility in process design. A wide variety of hole geometries, complex surface structures or the finest contours can be generated. In order to realize such processes, not only the appropriate system technology but also a correct process setting is required, which is a challenging task due to the large number of adjustable parameters. Thanks to many years of experience

with ultrashort pulse laser processes, we are your ideal partner

for the successful implementation of your application!

PROFESSIONAL PROCESS ADJUSTMENT

The ultrashort pulse laser is a complex tool with a large number of adjustable parameters. Parameters such as the pulse energy, the focus diameter, the repetition rate, the feed rate, the angle of attack and the hatch distance have a significant influence on the quality and speed of the machining process, to name just a few. Thus, setting the machining process with the ultrashort pulse laser to achieve the optimum machining result is extremely complex.

In many years of extensive research, LightPulse LASER PRECISION has worked out the fundamentals of laser-matter interaction and investigated quality-reducing effects in detail. This fundamental knowledge opens up a knowledge-based approach to process development. Thus, a more cost-efficient process adjustment is possible compared to a process adjustment based on a sole parameter study. Furthermore, we implement applications for you that you may have thought to be impossible until now.

If you have an idea for an application that can be realized with the ultrashort pulse laser, please contact us! In a cost-free initial consultation, we will discuss the basic feasibility and provide an estimate of the expected effort required to set up the process. Drilling processes for generating a hole geometry defined with an accuracy of a few micrometers, for example, are significantly more complex than black marking on a stainless steel component. If you decide to develop the machining process with us, we verify the successful process setting with the production of sample parts.

In many years of extensive research, LightPulse LASER PRECISION has worked out the fundamentals of laser-matter interaction and investigated quality-reducing effects in detail. This fundamental knowledge opens up a knowledge-based approach to process development. Thus, a more cost-efficient process adjustment is possible compared to a process adjustment based on a sole parameter study. Furthermore, we implement applications for you that you may have thought to be impossible until now.

If you have an idea for an application that can be realized with the ultrashort pulse laser, please contact us! In a cost-free initial consultation, we will discuss the basic feasibility and provide an estimate of the expected effort required to set up the process. Drilling processes for generating a hole geometry defined with an accuracy of a few micrometers, for example, are significantly more complex than black marking on a stainless steel component. If you decide to develop the machining process with us, we verify the successful process setting with the production of sample parts.

PROCESS DEVELOPMENT

Depending on the process, setting the optimum machining parameters requires varying degrees of effort. Each application brings unique requirements that must be taken into account. These can be special materials, challenging geometry specifications or tight tolerances. Thanks to both our fundamental knowledge and our practical experience, we get the most out of your process for you. " Is not possible" only exists when it is a physical impossibility.

SUPPLY CHAIN

The ultrashort pulse laser is the right tool for many micromachining applications, but pre- or post-processing of the workpiece may be required. Thanks to our network, we also support you in this respect. We take care of upstream or downstream process stages so that you can reach a solution as efficiently as possible. In this way, you have a competent contact person for several processing steps and do not have to take care of everything by yourself.

PRE-PRODUCTION SERIES

We manufacture individual pieces for you such as prototypes or also pre-series in small to medium quantities. Pre-series production is an important intermediate step to get from a single piece to a reliable series production. Many factors only come into play when large volumes are produced. Thus, we support you in getting processes and products ready for series production as well as in transferring them into series production.

MEASUREMENT

At least as important as an optimal process is a reliable way to measure the manufactured components. Thanks to a calibrated digital microscope, we can provide you with measurements accurate down to below 1 µm

with an outstanding image quality. If even the smallest details are important, we have access to a scanning electron microscope (SEM). In this way, even the finest details are not missed! Depending on the implemented process, contact angles

can be measured as well as metallographic examinations

can be carried out.

PROCESSING EXAMPLES

LightPulse

LASER PRECISION has experience in a wide range of machining processes using the ultrashort pulse laser.

We can offer the following processes:

We can offer the following processes:

- Micro drilling

- Fine cutting

- Rotational machining / machining of rotationally symmetrical components

- Surface processing like structuring, micro engraving, thin film ablation

- Surface functionalization

- Laser marking

YOUR CONTACT PERSON

Are you interested in process development?

We look forward to hearing from you!

Phone: +49 (0)160 99802302

Email: info@light-pulse.de

We look forward to hearing from you!

Your personal contact:

Dr.-Ing. Christian Freitag

Email: info@light-pulse.de