Surface functionalisation

New surface properties thanks to laser structuring

Modification of material properties with the aid of the ultrashort pulse laser

The properties of surfaces can be specifically changed by structuring them with ultrashort pulse lasers. For example, laser-generated structures can be used to make a steel surface water-repellent (hydrophobic). Water-repellent properties are achieved through self-organised structures in the micro- and nanometre range.

The advantages of surface functionalisation with the ultrashort pulse laser are:

Minimal heat input.

This means that even very thin (a few 10 µm) and heat-sensitive materials can be functionalised.

Free shaping. The laser as a flexible tool allows the processing of surfaces of any shape.

Structuring instead of coating. The change in the properties of the surfaces is achieved by laser structuring alone. An additional coating is not necessary.

Free shaping. The laser as a flexible tool allows the processing of surfaces of any shape.

Structuring instead of coating. The change in the properties of the surfaces is achieved by laser structuring alone. An additional coating is not necessary.

The technology of surface functionalisation

With the ultrashort pulse laser it is possible to induce self-organizing structures

on a material surface. The laser beam is moved over the surface of the workpiece, normally with a scanner system. Which structures are formed depends on a multitude of parameters, whereby the energy density of the laser beam, the pulse and line overlap as well as the total number of processing steps performed are the most important influencing factors. At a low energy density below the ablation threshold, self-organizing, periodic surface structures (so-called LIPSS) of the order of the wavelength of the laser beam form. The alignment of these structures depends on the polarization of the laser beam. If energy density, pulse and line overlap and the number of processing steps are increased, bumps with dimensions of a few micrometers are formed. If the energy input is too high, pronounced depressions are formed and the surface is roughened considerably. These three types of structure are shown as examples in the picture below.

The structure of a surface can be optimized with regard to various functionalities

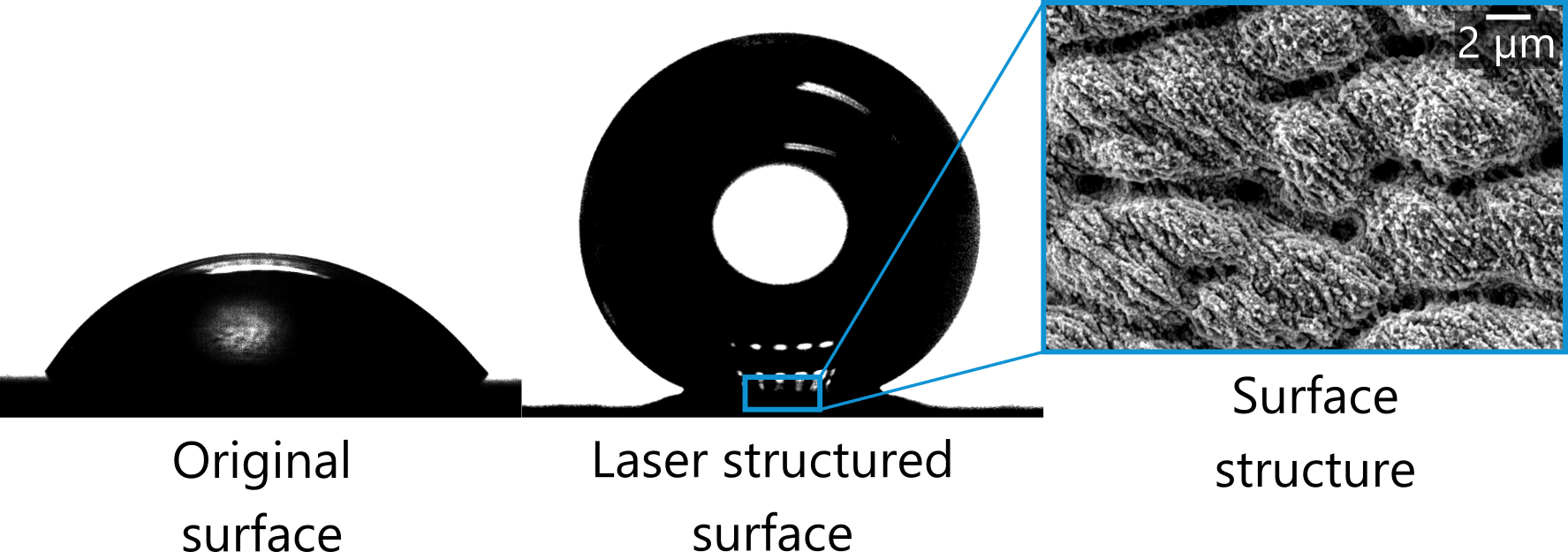

(hydrophobicity, frictional resistance, ...). For a hydrophobicity

(water-repellent property) of a surface, bumps with sizes of a few micrometers (> 5 µm) with a superimposed nanostructure have proven to be optimal. The effect of such a structure on a drop of water is shown in the following picture. The basic material is steel. Untreated, the steel surface is hydrophilic and is well wetted by the water drop. If the surface is suitably structured with the ultrashort pulse laser, it becomes water-repellent. Contact angles between the water drop and the surface >160°

are possible, which causes the water drop to roll off the surface. Such a surface structure is shown as a section in the picture below. You can see the combination of a bumps structure and a superimposed nanostructure.

The surface structure is a major factor influencing the functionality of a surface. However, water-repellent properties in particular are only achieved by a combination of the right surface structure and suitable chemical properties of the surface. Numerous publications have shown that a laser-structured surface must first be exposed to the ambient air for several days before water-repellent properties are achieved. It should also be noted that contamination or damage to the surface structure has a negative effect on the water-repellent properties. These special features must be taken into account if the surface functionalisation by means of ultrashort pulse laser is to be implemented industrially.

Some exemplary results of surface functionalization by means of ultrashort pulse lasers can be seen in the following picture gallery.

Some exemplary results of surface functionalization by means of ultrashort pulse lasers can be seen in the following picture gallery.