Materials

Wear-free machining of any materials

Machinable materials

The laser is a versatile tool that allows the processing of a wide variety of materials. Typical materials that can be processed with the laser are ferrous and non-ferrous metals

(steel, aluminium, copper, measurement, precious metals, ...) and ceramics

(aluminium oxide, silicon nitride, ...). Due to non-linear absorption effects, ultrashort laser pulses can also be used to process materials that are normally transparent to light, such as glass or silicon.

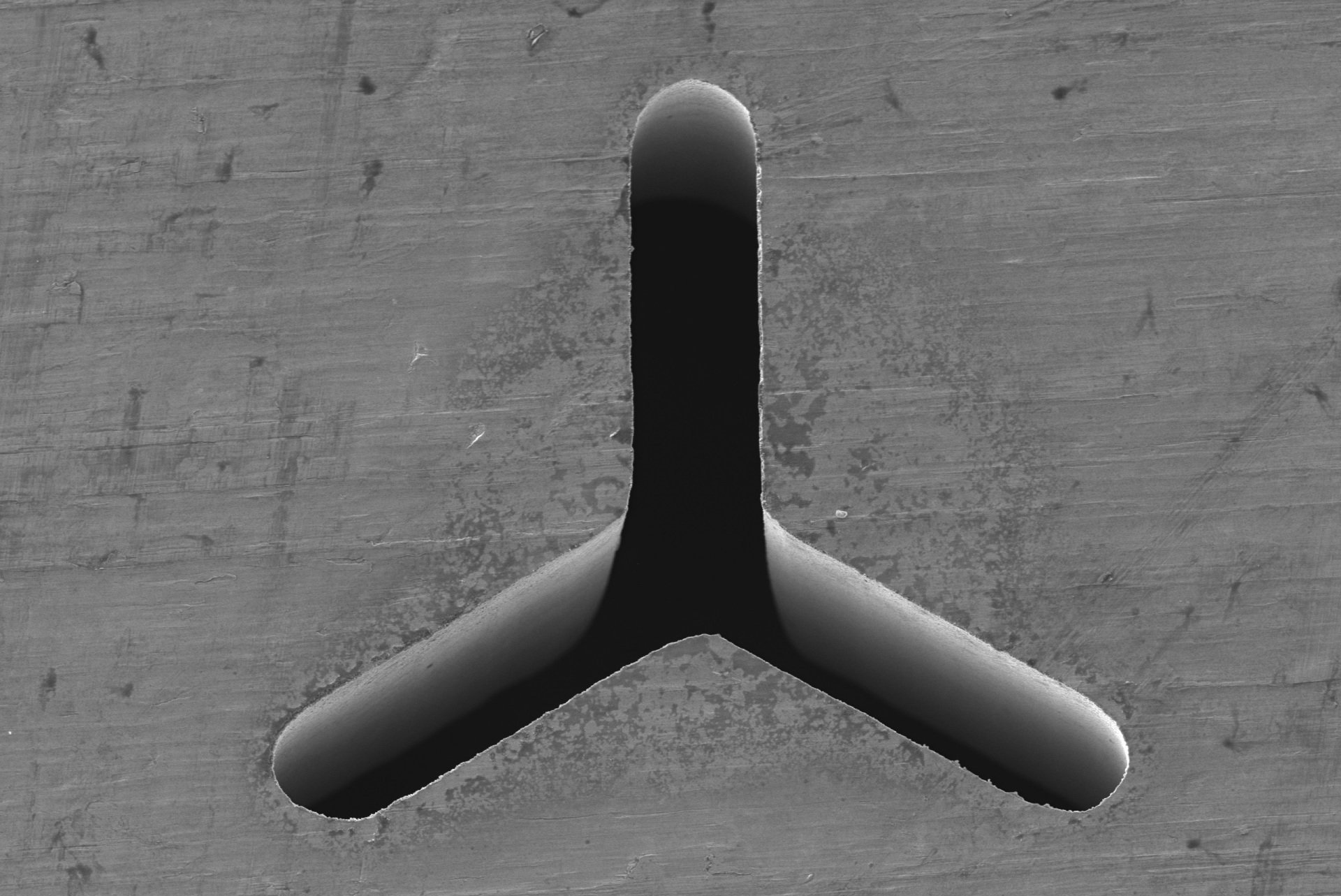

Melt-free machining of metals

The use of pulse durations of a few picoseconds and shorter allows the high-quality processing of metals. The short interaction time of the laser radiation with the material during a pulse and the high intensities lead to a quasi instantaneous vaporisation of the material. The formation of melt can be largely avoided with suitable process control. Geometry tolerances of less than 1 µm can be achieved, regardless of which metal (steel, aluminium, copper, brass, gold, platinum, ...)

is being processed.

Force-free machining of difficult-to-machine materials

Ceramics such as silicon nitride or minerals such as sapphires and rubies

are difficult to machine due to their hardness. Machining with the ultrashort pulse laser, on the other hand, is force-free. Thanks to the high instensities of the ultrashort pulse laser in the focus, the material is vaporised quasi instantaneously. There is no frictional contact between the workpiece and the tool. This means that even hard materials can be processed precisely and without wear.

High quality processing of transparent materials

Transparent materials such as glass

can also be processed with the ultrashort pulse laser. Even wavelengths for which the material is normally transparent are absorbed due to the high intensities in the focus thanks to non-linear absorption effects. In this way, glass can be drilled, cut or machined on the surface. These possibilities for micromachining open up a wide range of applications, for example in medical technology.

High-quality laser processing of CFRP

Fibre composites, especially carbon fibre reinforced plastics (CFRP), are challenging for laser processing due to the different thermal properties of the composite partners.

LightPulse LASER PRECISION has many years of experience in the laser processing of composites and is the ideal partner for high-quality laser processing of CFRP.

LightPulse LASER PRECISION has many years of experience in the laser processing of composites and is the ideal partner for high-quality laser processing of CFRP.